In the semiconductor industry, the geometrical quality of thin wafers plays a vital role in device performance. When evaluating substrates — whether silicon, sapphire, or other materials — technical parameters like TTV, Bow, Warp, and TIR are frequently cited. These metrics directly influence manufacturing yield and downstream processes.

What Do These Metrics Mean?

TTV (Total Thickness Variation)

TTV describes the difference between the wafer’s thickest and thinnest points when measured against a reference plane. Typically, this measurement is made while the wafer is clamped, and the result is expressed in micrometers (µm).Bow

Bow quantifies the deviation of the wafer’s center point from a reference plane when the wafer is in a free (unclamped) state. A positive bow indicates that the center is convex relative to the plane; a negative value means it is concave.Warp

Warp measures the maximum variation on a freely supported wafer between the highest and lowest surface points relative to a reference plane. This metric captures overall distortion, including twist or warp across the entire wafer surface.TIR (Total Indicated Reading)

When the wafer is clamped, TIR is defined as the maximum vertical distance between surface points, using a reference plane that minimizes the sum of deviations across all measured sites.

Why These Parameters Matter

These flatness and thickness metrics have significant implications for semiconductor processing:

Photolithography: Uneven wafers can lead to focusing issues and misalignment during patterning.

Chemical Mechanical Polishing (CMP): Variations in thickness or warpage can cause non-uniform polishing, affecting surface quality.

Deposition of Thin Films: Bow or warp can lead to uneven film growth, which impacts device uniformity and performance.

Assembly and Packaging: Large TTV or warp may cause issues when bonding or stacking wafers, leading to defects or reduced yield.

Standards and Measurement Techniques

Industry standards (for example, SEMI specifications) define how to measure these parameters accurately and consistently. Metrology tools include non-contact capacitance sensors, interferometry, and structured light projection, which provide high-precision surface profiling. Automated metrology systems are now widely used to monitor wafer shape, TTV, and flatness in high-volume production.

Why This Matters for 12-Inch Sapphire Wafers

For large-diameter substrates such as 12-inch (300 mm) sapphire wafers, tightly controlled flatness parameters like TTV, bow, warp, and TIR are even more critical:

Larger wafers are more susceptible to warpage or bending due to internal stress or thermal treatment.

A low TTV ensures thickness uniformity, which is essential for processes like epitaxy or thin-film deposition.

Precise bow and warp control helps maintain high yield in photolithography and CMP steps.

Accurate TIR contributes to stable clamping during processing, reducing deformation during handling.

By offering premium 12-inch sapphire wafers with excellent flatness and very low variation in these key metrics, manufacturers can significantly improve process stability and yield.

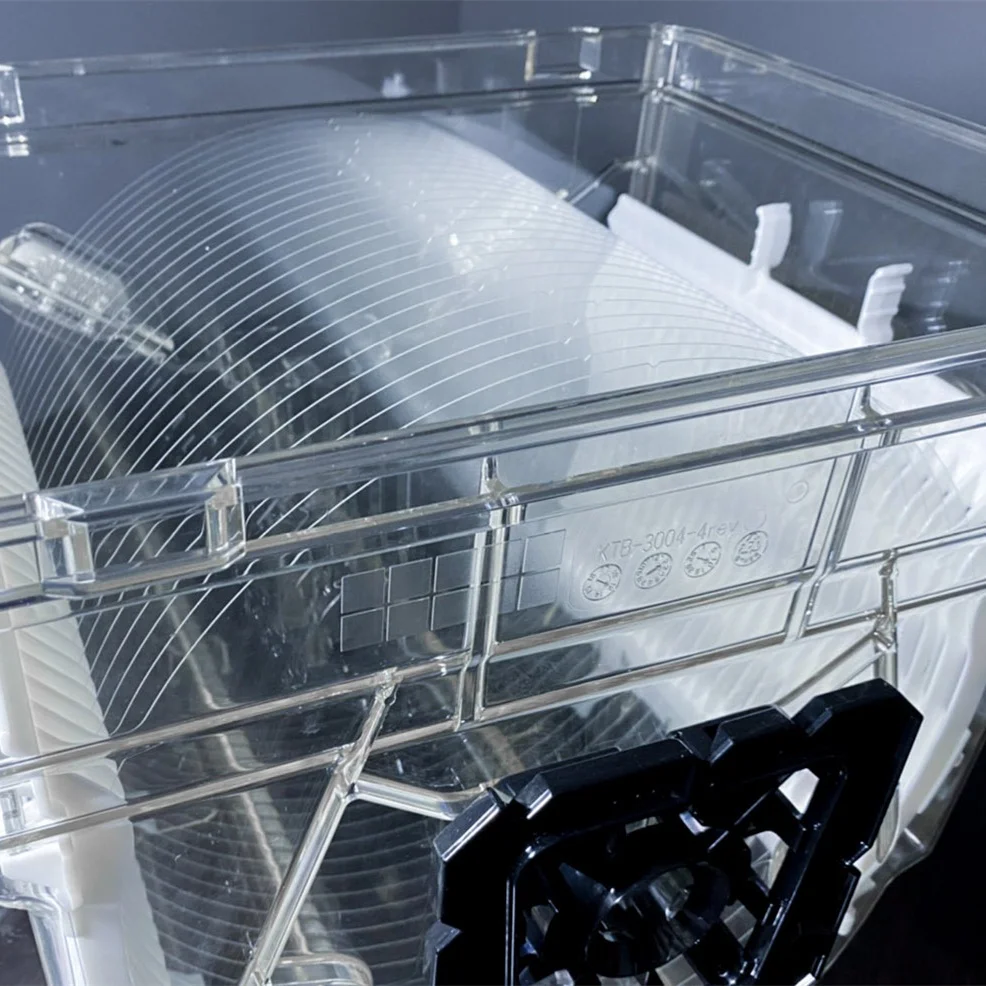

Our Offering: High-Precision 12-Inch Sapphire Wafers

We supply 12-inch sapphire wafers that meet stringent flatness specifications, featuring tight TTV, minimal bow and warp which together support superior performance in advanced semiconductor and optoelectronic applications.

Final Thoughts

Understanding and controlling parameters such as TTV, bow, warp, and TIR is essential for anyone working with high-performance substrates. These metrics are not just technical jargon; they reflect real-world manufacturing outcomes. When using high-quality 12-inch sapphire wafers optimized for these parameters, companies can minimize defects, enhance device uniformity, and boost overall production efficiency.