Overview

The 6 inch sapphire substrate is a high precision wafer developed for advanced semiconductor and optoelectronic devices.

It is manufactured from single crystal aluminum oxide (Al₂O₃) using high temperature crystal growth technology.

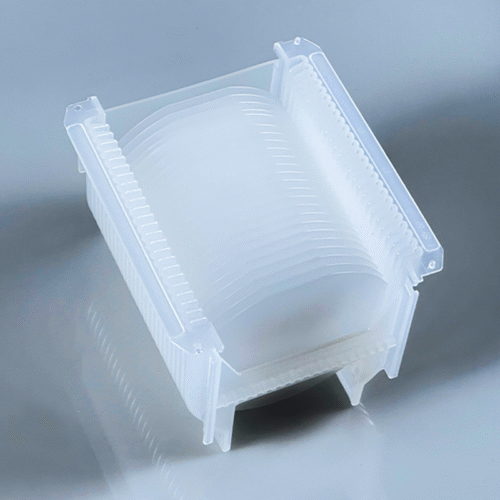

Each wafer offers excellent optical transparency, high mechanical strength, and chemical durability.

Available in both SSP (single side polished) and DSP (double side polished) formats, it supports a wide range of device fabrication processes.

6 Inch Sapphire Wafer Specification

| Parameters | Specifications |

| Material | High Purity Single Crystal Al2O3 |

| Crystal Growth Method | Kyropoulos (KY) Method |

| Orientation | C-plane (0001) (Off-axis available) |

| Diameter | 150.0 ± 0.2 mm |

| Thickness | 300 – 1500 um ± 5 um (Customizable) |

| Notch Orientation | A-plane |

| TTV | ≤ 5 um |

| Bow | ≤ 15 um |

| Warp | ≤ 40 um |

| Surface Finish (Front) | Epi-ready, CMP Polished, Ra≤ 0.3 nm |

| Surface Finish (Back) | Epi-ready, CMP Polished, Ra≤ 0.3 nm |

| Edge Profile | SEMI Standard Bevel |

| Cleanliness | Class 100 Cleanroom Packed |

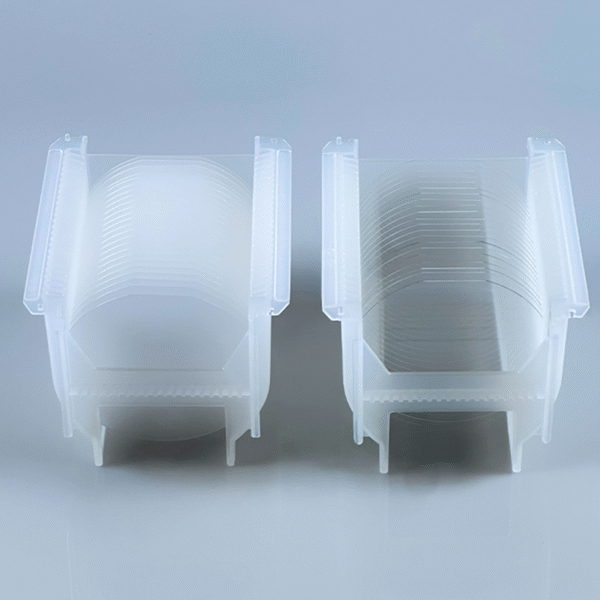

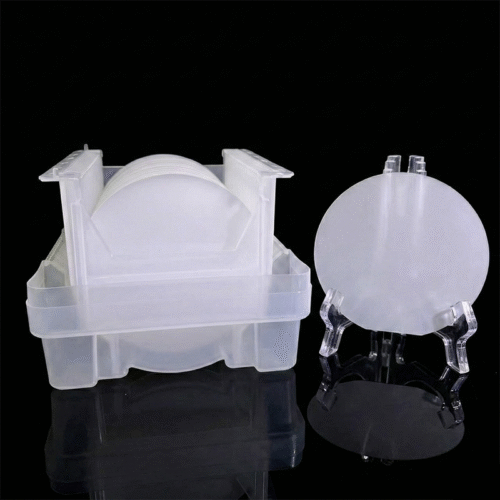

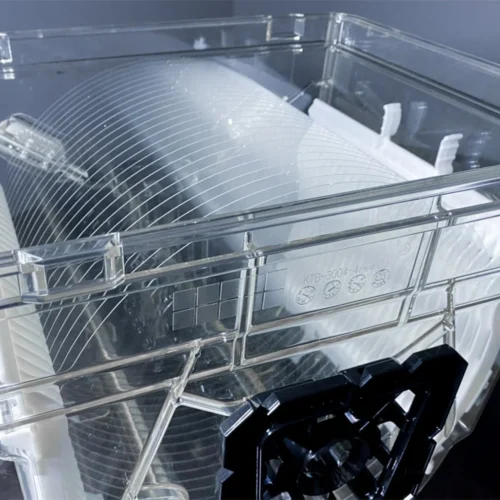

| Packaging | 6 inch Cassette (≤25 pcs) |

Material and Crystal Properties

Material Composition

Al₂O₃ content above 99.999% ensures outstanding purity and uniformity.

This minimizes defects and enhances the reliability of thin film growth.

Crystal Growth

Produced using the Kyropoulos method for stable lattice orientation.

Crystal structure belongs to the trigonal system with a high degree of symmetry and hardness.

Orientation Options

Standard orientation is C-plane (0001).

Optional planes such as A-plane or R-plane are available on request for optical or piezoelectric applications.

Surface Condition

Mirror-polished surface with Ra ≤ 0.3 nm on polished sides.

The surface is suitable for epitaxy, lithography, and thin-film deposition.

Performance Highlights

Thermal Management

Sapphire provides strong thermal conductivity and heat resistance.

It supports GaN and AlN epitaxial layers under high power operation.

Mechanical Strength

The wafer maintains structural stability during thermal cycles and plasma processes.

It resists cracking and deformation during device fabrication.

Optical and Electrical Performance

Sapphire is transparent from UV to IR wavelengths.

It also provides excellent electrical insulation and dielectric stability.

Chemical Resistance

The surface resists acid, alkali, and plasma corrosion.

Ideal for deposition and etching environments.

Dimensional Precision

Low TTV, bow, and warp ensure smooth wafer alignment and precise pattern transfer.

Typical Applications

- LED Production: Blue, UV, and white LED chip fabrication.

- Semiconductor Devices: GaN-on-sapphire and AlN-on-sapphire structures.

- RF Electronics: Power amplifiers, microwave, and high-frequency components.

- Optical Components: Windows, lenses, and transparent protective covers.

- Research: Material testing and wide bandgap semiconductor development.

Customization & Quality Assurance

- Orientation and off-cut angle customization available.

- Thickness and surface polish tailored to process needs.

- Edge bevel and chamfer according to SEMI specifications.

- 100% visual inspection and metrology verification before shipment.

- Packaging in Class 100 cleanroom environment with traceable lot control.

Advantages of Choosing This 6 Inch Sapphire Wafer

This wafer provides the balance of cost efficiency and technical performance.

It supports both pilot production and mass manufacturing.

The high purity and superior flatness improve epitaxial yield and uniformity.

It is a trusted choice for LED, optical, and high-frequency electronic systems.

Looking for larger diameters?

Check our 8 Inch Sapphire Wafers and 12 Inch Sapphire Wafers for next-gen semiconductor manufacturing.