In the semiconductor industry, packaging evolves with technology. For decades, 6 inch and 8 inch wafers were the standard. Manufacturers used open cassettes and storage boxes to ship them. However, the industry has shifted to 12 inch (300mm) wafers. With this shift, the packaging changed completely. We no longer use simple cassettes for shipping. We use the FOSB (Front Opening Shipping Box).

Why did this change happen? It is not just about size. It is about protection, automation, and yield. Here are the main reasons why 12 inch wafers require FOSB.

1. The Challenge of Particle Contamination

The biggest enemy of a semiconductor is dust.

- Small Wafers (2-8 Inch): Older technology nodes (like 0.18 micron) were less sensitive to tiny particles. We could ship wafers in a cassette, put the cassette in a plastic box, and vacuum seal it in a bag.

- 12 Inch Wafers: These wafers usually contain chips made with advanced nodes (like 28nm, 14nm, or even smaller). These chips are extremely sensitive. Even a microscopic particle can kill the yield.

A traditional cassette is open. It exposes wafers to air when you open the box. A FOSB is a sealed mini environment. It keeps the internal air clean. It protects the wafers from the dirty air of the warehouse or truck. This is critical for maintaining high yields.

2. Compatibility with Full Automation

Handling 300mm wafers by hand is dangerous and difficult.

- Weight: A fully loaded cassette of 25 wafers at 300mm is heavy. It is risky for a human to carry it.

- Risk: Dropping a box of 12 inch wafers could cost tens of thousands of dollars.

Therefore, 12 inch fabs are fully automated. They use AMHS (Automated Material Handling Systems). A FOSB is designed for robots, not humans.

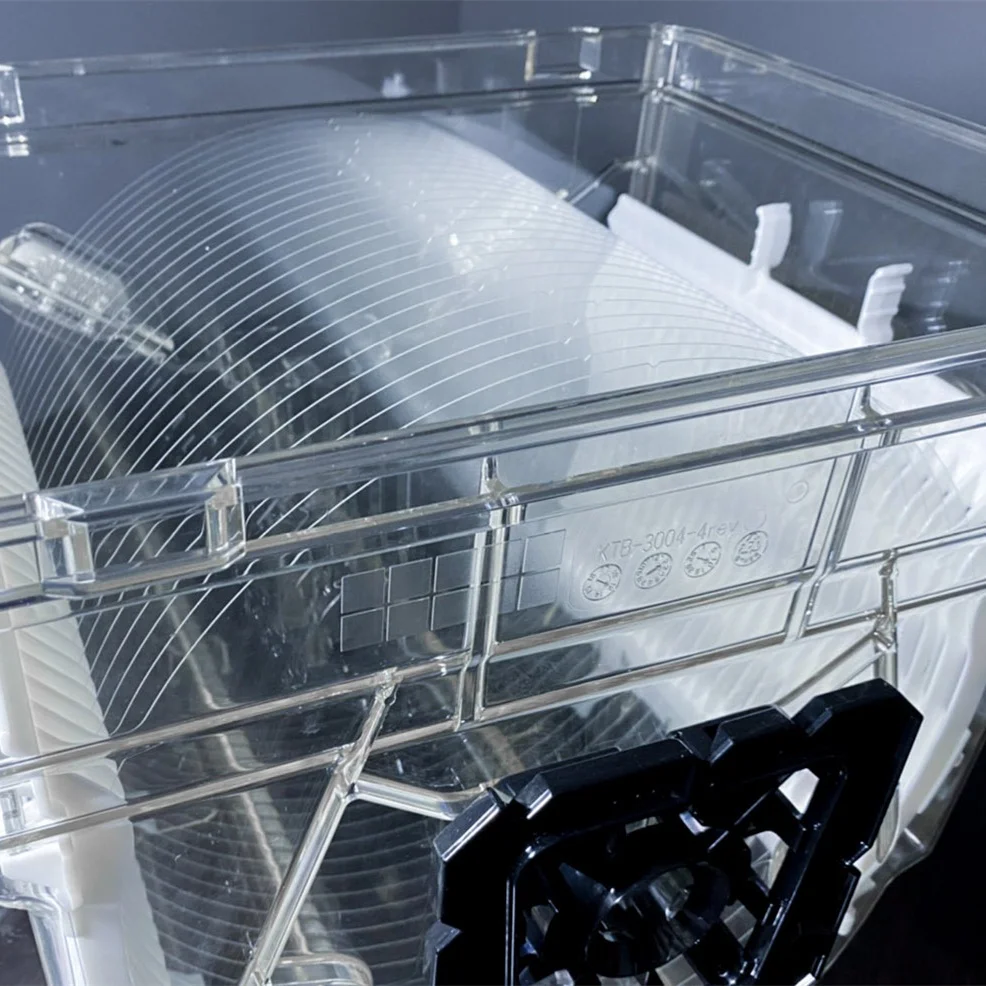

- It has a standard “mushroom” handle on top for overhead hoists (OHT).

- It has kinematic coupling pins on the bottom for precise placement.

- It has a front door that robots can open automatically.

Old style cassettes do not have these standard features. They were designed for manual handling or simple conveyor belts. They cannot work in a modern “Lights Out” fab.

3. Superior Shock and Vibration Protection

Shipping wafers is rough. Trucks vibrate and planes shake.

- Cassette Limitations: In the past, wafers rattled inside loose cassettes. This caused friction. Friction creates dust. In bad cases, wafers would crack.

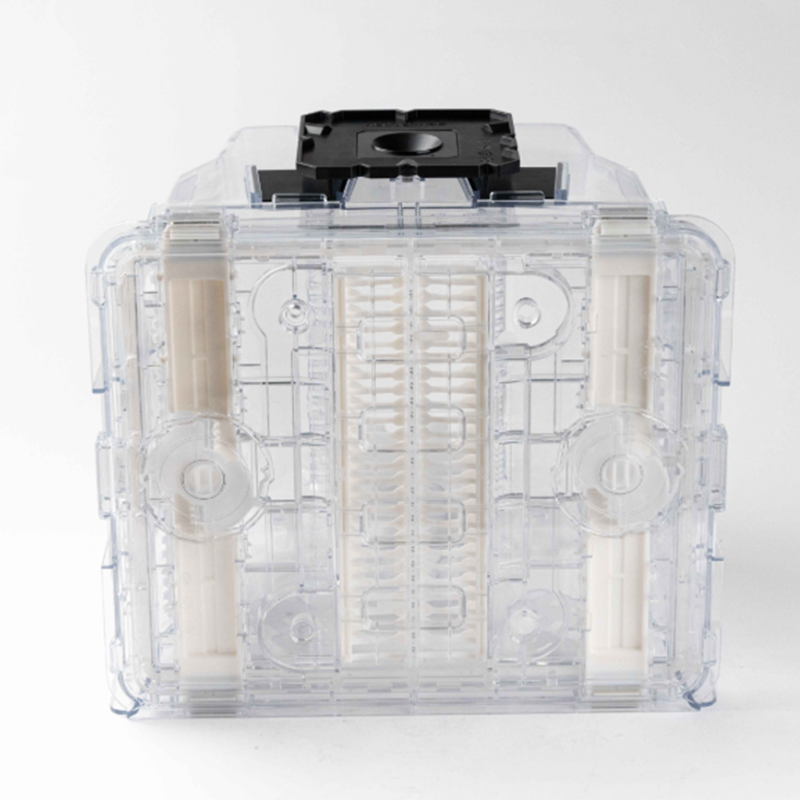

- FOSB Design: A FOSB is an engineered shipping solution. It is made of rigid Polycarbonate (PC). Inside, the wafers are held tight. The teeth and slots are designed to grip the wafer edges firmly. This prevents movement during transport. The FOSB acts like a shock absorber. It ensures the wafers arrive without scratches or cracks.

4. The Transition from Shipping to Processing

Efficiency is key in modern manufacturing.

- The Old Way: You receive a box. You open it manually. You take out the cassette. You put the cassette into a machine. This takes time and adds human error.

- The FOSB Way: The FOSB arrives. You clean the outside. You place it directly on the load port. In some cases, the FOSB can be used to transfer wafers directly to a FOUP. The design of the FOSB is very similar to the FOUP used inside the fab. This makes the transfer process seamless and clean.

The transition from 8 inch to 12 inch wafers was a huge leap in technology. The packaging had to evolve too. The traditional cassette and box method was no longer good enough. The FOSB provides the necessary cleanliness, automation compatibility, and physical protection.

If you are manufacturing or transporting 300mm wafers, you cannot compromise. You need high quality FOSBs to protect your valuable assets.

Buy 12 Inch Sapphire Wafers

Direct from a Specialized 300mm Sapphire Substrate Manufacturer

Contact Us

Are you looking for reliable 12 inch FOSBs? We offer durable PC carriers with optional RFID tracking. Contact us today for a quote.