In the world of semiconductor manufacturing, the smallest particle can cause the biggest problem. This is especially true for large-format 12-inch (300mm) sapphire wafers.

As we scale up from 4-inch or 6-inch sizes, the surface area increases dramatically. This gives dust, organic residue, and metallic ions more space to hide. At Minnoptics, we believe that a wafer is only as good as its surface cleanliness.

Here is why factory-level cleaning is critical for your yield and how we ensure perfection from our tank to your facility.

The High Cost of Low Cleanliness

Why do we obsess over particles smaller than a micron? Because for applications like MicroLED or RF filters, a single particle is not just a spot of dirt. It is a dead pixel. It is a short circuit. It is a failed device.

If a sapphire substrate has high particle counts or surface haze, the epitaxial growth (Epi-growth) layer will have defects. These defects spread upward through the device layers. This leads to yield loss at the very end of your production line. That is the most expensive time to fail.

Why You Should Not Rely on “Re-Cleaning”

Some buyers believe they can buy cheaper, standard-washed wafers and clean them again in their own fab. For 12-inch sapphire, this is a dangerous strategy for three reasons.

Handling Risks: A 300mm sapphire wafer is heavy and hard. Every time you move it to a cleaning tank, you risk scratching the surface or chipping the edge.

Chemical Complexity: Sapphire is chemically different from Silicon. Standard silicon cleaning lines often fail to remove specific organic residues from sapphire surfaces without damaging the polish.

Time is Money: Your engineers should focus on device fabrication, not on fixing raw material issues.

This is why we deliver “Epi-Ready” surfaces. This means you can take the wafer out of the box and put it straight into your MOCVD or PVD equipment. No re-cleaning is needed.

Our Process: The MinnOptics Standard

We do not just “wash” our wafers. We engineer the surface. While we protect our specific recipes, our cleaning line follows a rigorous multi-stage protocol designed specifically for large-diameter sapphire.

Chemical Stripping: We use a modified chemical sequence to strip all organic residues and polishing slurry.

Megasonic Energy: We use precise acoustic waves to dislodge sub-micron particles from the surface without damaging the crystal lattice.

Surface Passivation: The final step ensures the surface is chemically stable and resistant to re-contamination from the air.

From Our Cleanroom to Yours

A clean wafer is useless if it gets dirty during shipping. We maintain a strict “Chain of Custody” for cleanliness.

1. Class 100 Packaging

As soon as the final dry is complete, the wafers move instantly to a Class 100 cleanroom environment. They are never exposed to regular air.

2. Vacuum Sealing

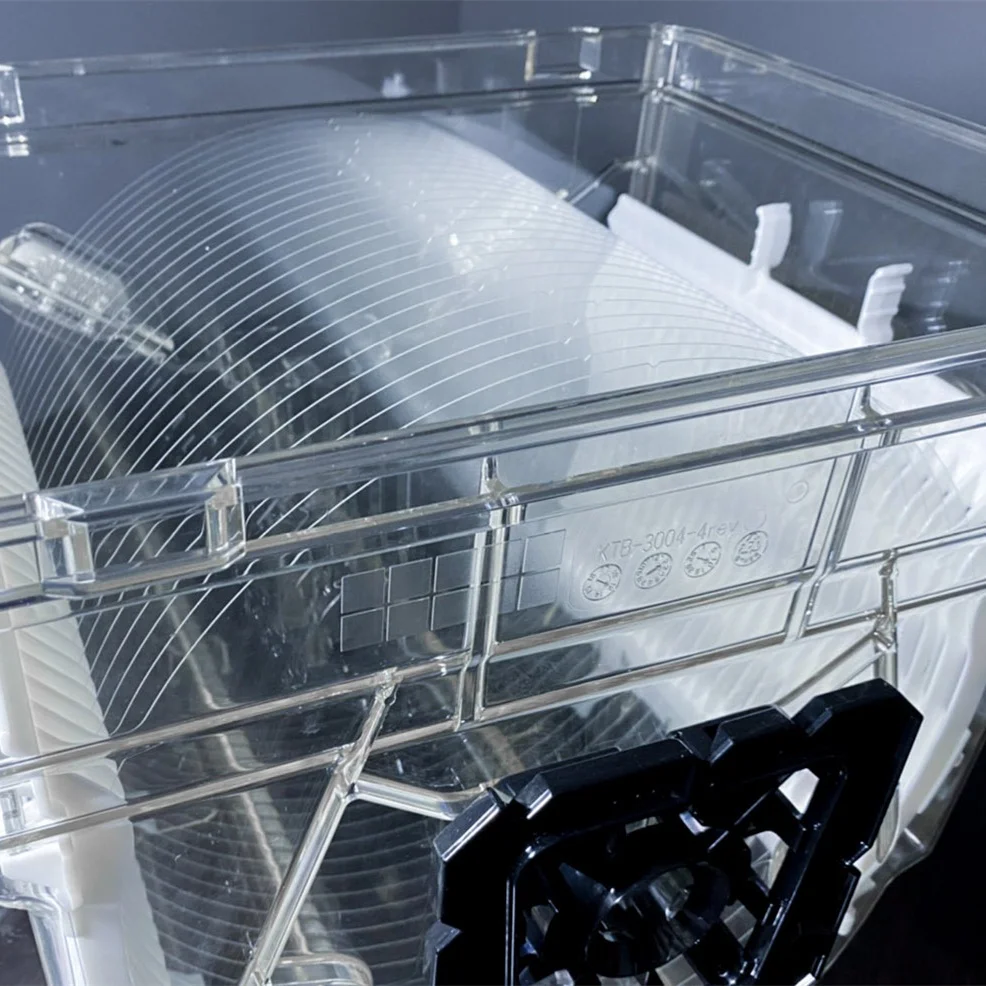

For 12-inch wafers, we use industry-standard FOSB (Front Opening Unified Pod) or single-wafer shippers. These containers are double-bagged and vacuum-sealed with Nitrogen purging. This prevents oxidation and keeps humidity out.

3. The Final Check

Before we seal the box, every batch undergoes an automatic surface inspection. We check for particles, scratches, and haze. If it does not meet the “Prime Grade” standard, it does not leave our factory.

Don’t let invisible particles destroy your valuable 12-inch process. Choose a partner who understands that cleanliness is quality.

Check the specifications of our 12 Inch Sapphire Wafers or contact our engineering team to discuss your strict particle count requirements.