As augmented reality (AR) hardware accelerates toward mass adoption, one of the biggest hurdles remains: how to deliver lightweight, high-performance smart glasses with excellent optical quality and efficient heat management. Emerging as a promising solution, silicon carbide (SiC) is increasingly being eyed as a foundational material in next-generation AR optics.

Why Silicon Carbide Is Ideal for AR Optics

Silicon carbide is a wide-bandgap semiconductor with several standout physical properties that make it highly suitable for AR waveguides and lenses:

High refractive index: SiC has a refractive index above 2.6, significantly higher than ordinary glass or polymer materials (typically around 1.5–1.9). This high index enables the design of more efficient diffractive waveguides, which can tightly confine and guide light.

Excellent thermal conductivity: SiC can dissipate heat rapidly, which is critical in AR systems where microdisplay engines can generate significant thermal loads.

Superior mechanical hardness: With a hardness close to that of diamond, SiC offers robustness and durability, reducing the risk of scratching or damage compared to softer optical materials.

Technological Advances: From Lab to Prototype

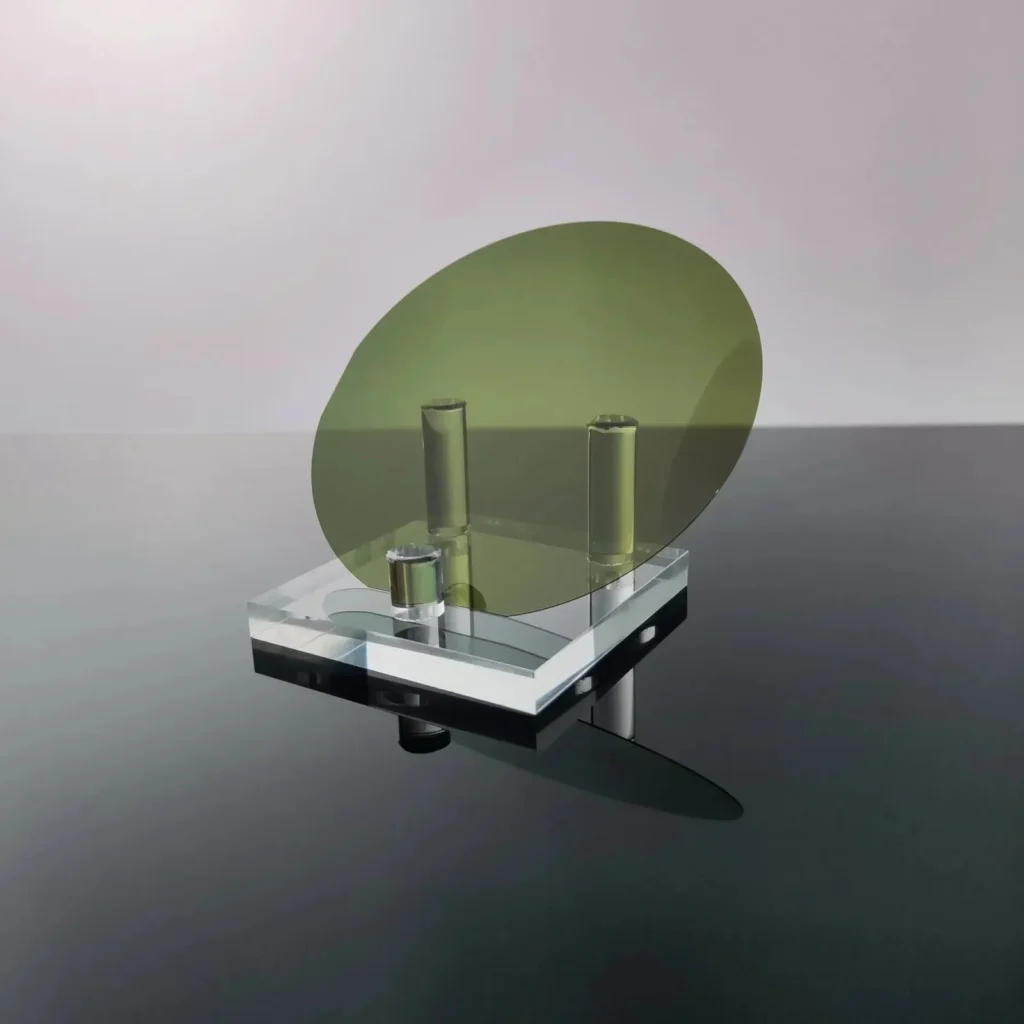

Researchers have made substantial progress in leveraging SiC for practical AR applications. A breakthrough from a university optics team demonstrated an ultra-thin, ultra-light diffractive waveguide lens made from SiC. The prototype lens weighs only 2.7 grams and is just 0.55 mm thick — thinner than typical sunglasses — yet capable of full-color display without the distracting “rainbow effect” common in many conventional AR devices.

This innovation relies on single-layer diffractive waveguide technology. Thanks to SiC’s high refractive index, only one layer is needed for full-color imaging, simplifying design and cutting down on bulk.

The underlying research has been described in academic work, highlighting the feasibility of mass production and prescription-lens integration, while preserving optical clarity and minimizing visual artifacts.

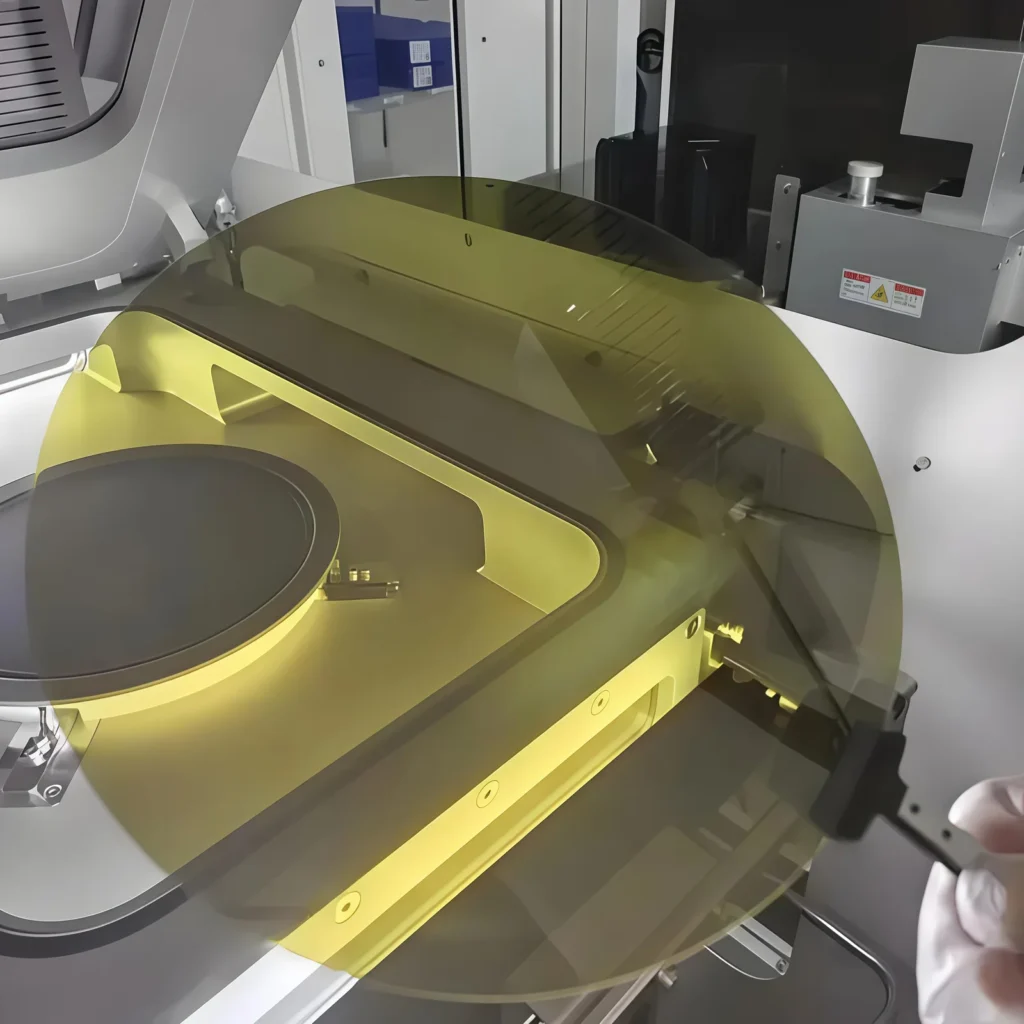

Overcoming Manufacturing Challenges

Despite its advantages, SiC’s inherent hardness and brittleness present manufacturing challenges. Traditional mechanical cutting is risky, as it can induce fractures or surface defects. To address this, some companies are turning to MicroJet laser technology, which uses a high-pressure water-jet–guided laser to perform “cold processing.” This method reduces thermal stress and maintains surface quality, enabling precise cuts and thin slices well-suited for AR waveguides.

Market Momentum and Industry Adoption

The AR industry is taking notice. According to recent industry analyses, AR eyewear is emerging as a compelling application for SiC, especially for semi-insulating SiC substrates.

Financial and market research also points to SiC’s rising strategic role: major AR players and material suppliers are increasingly aligning around SiC as a key enabler for high-performance waveguide optics.

A further boost to confidence came with the public demonstration of SiC-based AR glasses featuring ultra-thin waveguides and wide field of view (FOV), signaling not just a lab curiosity but a viable path for commercial AR devices.

Why This Matters for Your Business

For companies producing or supplying SiC wafers, the growing demand for optical-grade SiC in AR could open up a significant new market. The unique combination of high refractive index, thermal stability, and mechanical robustness makes SiC wafers a highly differentiated product in the AR materials supply chain.

If you’re looking to partner with a high-quality SiC wafer supplier, our SiC products are well-positioned to meet the rigorous demands of AR optical applications.

Future Outlook

Scale-up potential: As manufacturing methods such as laser slicing and precision etching mature, production yields are expected to improve, driving down costs.

Broader adoption: AR hardware makers will likely embrace SiC to build sleeker, more power-efficient, and more reliable devices.

New use cases: Beyond consumer glasses, SiC waveguide technology could expand into enterprise, industrial, and medical AR applications, where performance and durability are especially critical.